Advanced Head Protection Systems

As industry-leading safety equipment specialists, we provide comprehensive Head Protection solutions designed to protect workers from impact, penetration, and electrical hazards. Our safety helmets combine cutting-edge ergonomic design with rigorous safety standards to deliver unmatched protection and comfort for all types of industrial and construction work.

What is a Safety Helmet?

A Safety Helmet (or hard hat) is a type of personal protective equipment (PPE) designed to protect the head from injury due to falling objects, impact with other objects, debris, rain, and electric shock. Modern safety helmets are engineered with advanced materials and suspension systems to absorb and dissipate the force of impacts, significantly reducing the risk of head injuries in industrial and construction environments.

Our Product Range

Certified Safety Equipment

Our comprehensive Head Protection product line includes specialized designs for construction, electrical work, industrial maintenance, and rescue applications. All our helmets meet or exceed ANSI, OSHA, and international safety standards, featuring robust construction, ergonomic design, and advanced safety features to protect workers in various high-risk environments.

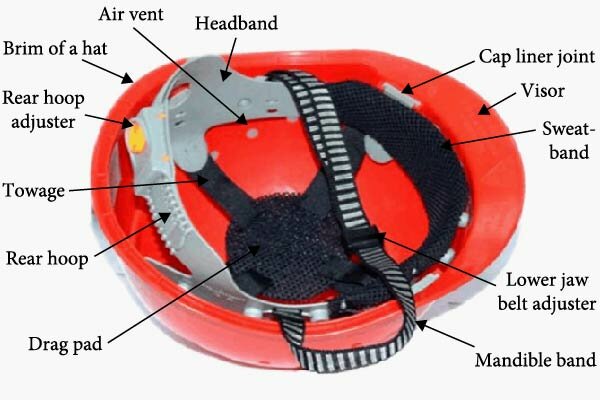

Key Components

Technical Specifications

Our Safety Helmets are engineered for maximum protection with components including high-impact resistant shells (HDPE, ABS, or polycarbonate), advanced suspension systems, energy-absorbing foam liners, and adjustable comfort padding. Each helmet is designed to meet specific impact resistance requirements and electrical insulation standards based on comprehensive safety testing.

Industrial Safety Helmets

Heavy-duty helmets designed for construction and general industry applications. Features include impact protection, ventilation systems, accessory slots, and compatibility with hearing and eye protection.

Climbing & Height Safety

Specialized helmets optimized for work at height. Features include chin straps, reduced weight, improved balance, and compatibility with fall protection equipment.

Electrical Protection

Insulated helmets for electrical workers. Features include dielectric materials, voltage protection ratings, and designs that prevent electrical conductivity.

Rescue & Emergency

Technical helmets for emergency response teams. Features include integrated lighting, communication systems, face shields, and enhanced impact protection.

Proper Fitting Process

Size Selection

Choose the correct helmet size based on head circumference measurements. The helmet should fit snugly without excessive pressure points.

Suspension Adjustment

Adjust the suspension system to ensure proper clearance between the shell and the head. The suspension should distribute weight evenly.

Chin Strap

Secure the chin strap (if applicable) to prevent the helmet from falling off during movement or in windy conditions.

Final Inspection

Check all adjustments, ensure the helmet sits level on the head, and verify that it doesn't obstruct vision or hearing.

Key Safety Benefits

Advantages of Our Helmets

Technical Specifications

Performance Parameters

Impact Resistance: Withstands impacts up to 100 Joules

Penetration Resistance: Protects against sharp objects and debris

Shell Material: High-density polyethylene (HDPE), ABS, or polycarbonate

Electrical Protection: Class E (20,000V) or Class G (2,200V) ratings

Temperature Range: -30°F to 140°F (-34°C to 60°C)

Standards Compliance: ANSI Z89.1, OSHA 1926, CSA Z94.1, EN 397

Industry Applications

Construction

Building construction, road work, demolition, and general contracting where head protection is required from falling objects and impacts.

Utilities & Energy

Electrical line work, power generation, and utility maintenance requiring protection from electrical hazards and impacts.

Manufacturing

Industrial plants, warehouses, and manufacturing facilities where overhead hazards and impact risks are present.

Mining & Tunneling

Underground operations with low clearance environments and potential rock fall hazards requiring specialized head protection.

Inspection & Maintenance

Comprehensive Safety Protocols

We provide detailed inspection guidelines and maintenance protocols to ensure helmet integrity and worker safety. Our programs include pre-use visual inspections, detailed periodic examinations, proper cleaning procedures, and clear criteria for helmet retirement. Regular inspection of shells, suspensions, and accessories is essential for maintaining head protection effectiveness and compliance with safety regulations.